KJW 76

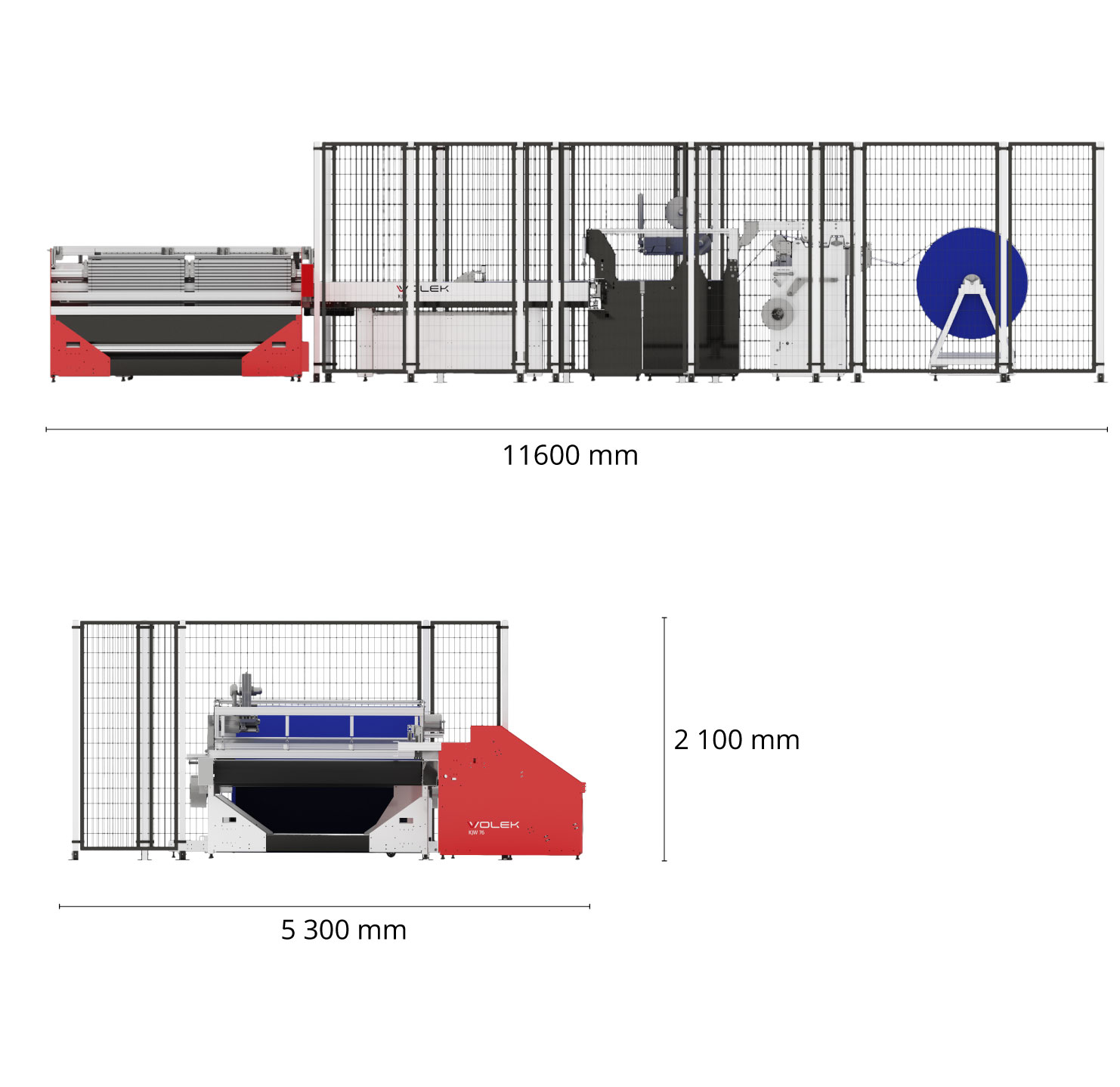

FULLY AUTOMATIC LINE FOR ROLLER BLINDS PRODUCTION

Our roller blinds production line can be customized and adapt to your needs.

OUTPUT:

up to 10 ready made blinds in one minute

up to 10 ready made blinds in one minute

Fabric roll

feeder

effective high speed feeder with an automatic edge setting module

Pneumatic

trimmer

Flexibility of pneumatic system, the powerful motors ensure smooth and clean cuts

Output

10 blinds

in one minute

Packing

line

possibility of extension with packing line to improve your business

Specification

Maximum width of the blinds 2400 mm

other sizes possible on request

Maximum length of the blind up to 2200 mm

other sizes possible on request

Inner diameter of the blinds tube - 25 mm or 32 mm

Maximum diameter of the fabric roll - 1200 mm

Maximum weight of the fabric roll - 2000 kg

Fabric feeder with automatic edge setting

An assembly that applies double-sided adhesive tape for attaching the blind's tube

An assembly that applies double-sided adhesive tape to glue the blind's channel

An assembly gluing the blind's channel

Pneumatic trimmer

A cart that pulls the fabric along the width of the fabric cut

Table with belt conveyor for feeding fabric to glue on the tube and roll up the blind

Tube feeding assembly

An assembly gluing on the tube and rolling the blind

Possibility of extension with a packaging line

other sizes possible on request

Maximum length of the blind up to 2200 mm

other sizes possible on request

Inner diameter of the blinds tube - 25 mm or 32 mm

Maximum diameter of the fabric roll - 1200 mm

Maximum weight of the fabric roll - 2000 kg

Fabric feeder with automatic edge setting

An assembly that applies double-sided adhesive tape for attaching the blind's tube

An assembly that applies double-sided adhesive tape to glue the blind's channel

An assembly gluing the blind's channel

Pneumatic trimmer

A cart that pulls the fabric along the width of the fabric cut

Table with belt conveyor for feeding fabric to glue on the tube and roll up the blind

Tube feeding assembly

An assembly gluing on the tube and rolling the blind

Possibility of extension with a packaging line